Call Us: 01702 292984 Email Us: info@cube3productdesign.co.uk

Much of what we buy is manufactured abroad, predominantly in China. This is usually cost driven. If it is cheaper to manufacture offshore, then would it not be cheaper to design and develop your product where it is going to be manufactured? Well, yes; potential vendors will offer design at a reduced rate or for free as part of the manufacturing contract. A tempting win for both sides? Actually, this approach is fraught with risk. Here’s why:

The design of your product could be compromised. Offshoring risks communication problems; no common language and mismatched time zones are barriers to clear and quick exchange of information. A lack of understanding of your market, customer and associated regulatory requirements could also impact your product resulting in sales and profits that never reach their full potential.

Where design is included as part of manufacture then the development of your product becomes an overhead to be minimised. Less value is attached to the importance of spending the time to get it right for the long-term success. If the design resource is hidden behind a manufacturer, then quality and track record are difficult to determine and there may be no alternatives on offer.

There is also the concern that your design data gets into the wrong hands with a copy of your product appearing shortly after your product is launched. Even with intellectual property protection in place, any dispute will take time and money to resolve and will come with inherent communication problems.

So, there are downsides to overseas product development but what about UK-based product design? To start with the UK has a world-class creative sector. It delivers inherent strategic and commercial benefits leading to business growth. This is possible because the UK is at the forefront of design education. This feeds into a large, diverse and effective product design sector. There will be a match for your product development needs.

UK design works in the global marketplace so if you market is in the UK, EU or worldwide then there will be the experience to deliver the right product. UK or overseas manufacture can be managed effectively with reliable and trusted vendors recommended, problems anticipated and avoided.

There are more basic advantages: You and your design company share the same language and working hours, so communication is easy and responsive. Meetings are easy to arrange and there are no cultural misunderstandings.

Product design is going to be a small proportion of the total cost to market but investing in UK design to get it right dramatically reduces the risk and expense of developing and manufacturing the wrong product. UK design is ideally placed to deliver the right product for your market.

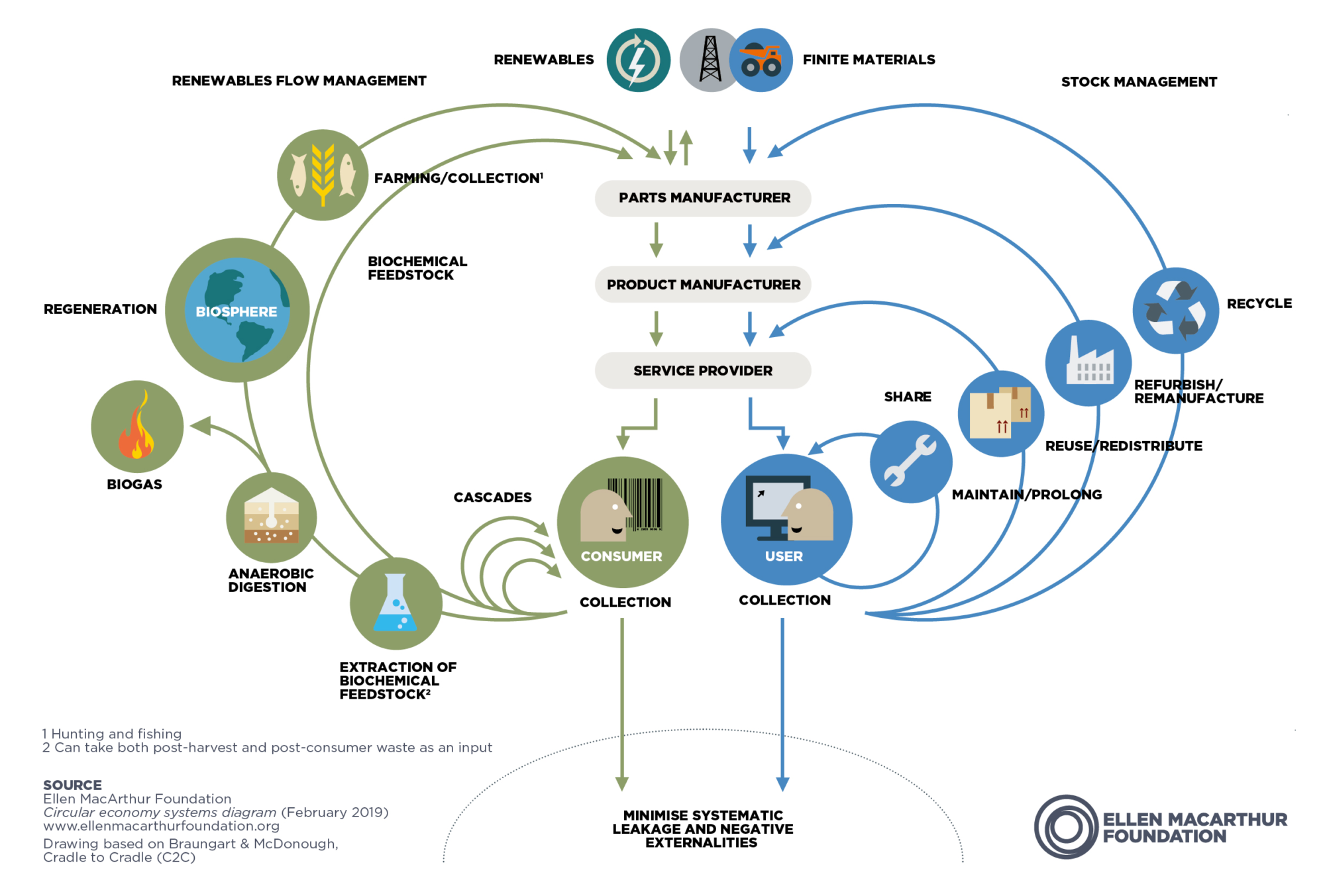

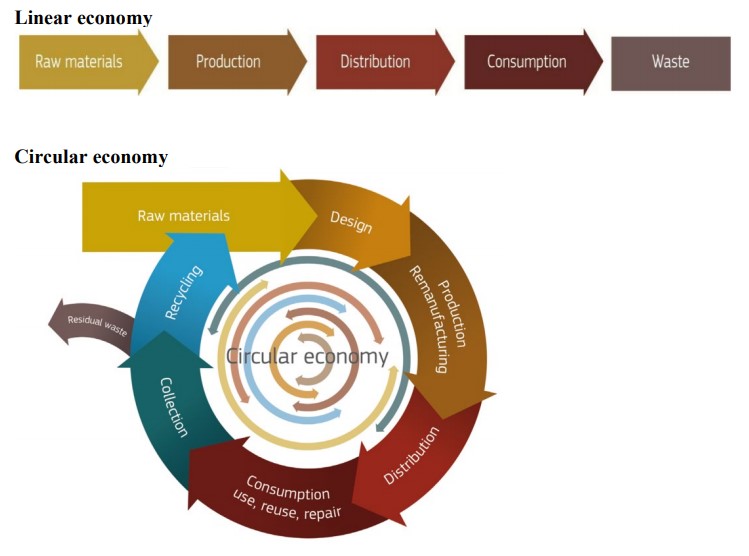

A lot has been written and talked about on the subject of sustainability and the circular economy. Many books have been written on the subject going into great detail, but in this blog I want to address the subject from the point of view of a start-up or existing business that does not have sustainability running through their veins yet. What practical things can be considered in developing new products without having to rethink your entire business model?

A lot has been written and talked about on the subject of sustainability and the circular economy. Many books have been written on the subject going into great detail, but in this blog I want to address the subject from the point of view of a start-up or existing business that does not have sustainability running through their veins yet. What practical things can be considered in developing new products without having to rethink your entire business model?

So you’re looking to engage with a design consultancy to design your next product. How do you get the design you want? The product that's going to beat the competition, the perfect product to make your company successful? A simple and clearly written design brief would be a good start!

It doesn’t matter if you are an inventor with an idea, a start up with new tech or an established SME with a range of products that you want to make more cost effectively. The single most important part of any new development is an effective design brief. Without one, it is almost impossible to develop a successful product.

This blog post will help you to write the perfect design brief that will be beneficial to you and the designer you engage with.

So what is a design brief?

A design brief is a document that provides the designer with all of the information they will need in order to complete the task and meet your expectations. It also allows you, the client, to focus on exactly what you want to achieve before any work is carried out.

A Product brief is critical to getting the most out of designers as they can focus on what is required and not waste time on the wrong tasks.

How to write a good design brief.

1. Information about you

Firstly you should start off by introducing yourself and your company. What is the nature of your business? What do you do? How long have you been doing it? What industry sector do you operate in and any niche market info you have. Be clear and concise and avoid unnecessary information that is not relevant to the product.

2. What is the product?

So the designers are going to need to know what it is you want them to design. What is it called? What does it do? What are the key features or benefits? What need does it fulfil or problem does it solve? How does it fit in with your other products? How is it better than the competitors’ products?

3. What are your aims or goals and why?

List them with reasons for each. Is it to increase sales, to obtain information from clients, to reduce manufacturing costs or to embrace a new technology for instance? How do you differ from the competition? There could be a number of reasons that I’ve not listed so please explain why as it will give the designers a much better understanding of the project.

4. Who is the target audience?

Ideally you should have researched this and should be able to tell the designers who the product is aimed at. Their age, sex, income, occupation, location and any other important information. Providing evidence of your research will give the designers more confidence that you understand who will buy your product.

5. Tell us what you don’t know

You may not have answers to all of these questions. This is okay, so long as you don’t guess or make stuff up! Just say in the brief that you don’t know and list one of your deliverables as completing the product design brief. It’s also fine to ask questions. Designers will question everything anyway, it’s what we do, so again, just make this part of the scope of work required.

6. Standards, compliance, environmental

What standards does the new product need to meet? What environmental conditions will the product need to withstand? Will it operate independently or part of a larger system? Be as specific as you can here but if you don’t know then say so.

7. Research

It may be useful to tell the designer how far you have come on your journey. If you have completed months of research, then mention it and include the research as an attachment to the document. If you have successfully or otherwise completed a round of concept generation then include this information to prevent the designer covering old ground.

8. Scope of the work required

It is important to clearly state the scope of the work that you wish a designer to undertake. You may only want them to create concept designs instead of a complete turn-key service from research to production. What are the deliverable you require?

9. Budgets and timescales.

Is there a specific launch date that is important? What is the retail price of the product? What finances do you have in place to fund the development? How much do you want to spend on the development? If there’s no specific launch date, what timescales are you looking to achieve?

10. Tips and techniques

The brief should be open enough to inspire ideas and creativity, yet specific enough to prevent drift from the core requirements? Define what’s not how’s - focus on goals not solutions so "strong and light” instead of "made from aluminium”. You should outline the creative challenges and expectations where known. The brief should always be as short and simple as possible so avoid long and complicated text.

Hopefully this gives you a good understanding of how to write a great product design brief. As designers we often get very poor briefs even from larger companies! It means that we have to invest more time and energy at the front end of a project just to figure out what the client wants.

Think of it like the foundations of a house – if the foundations are not well planned and solid, the house may collapse!

Should you be considering the use of additive or subtractive manufacturing techniques for you next product?

Firstly, let's look at the basic types of additive manufacturing technologies.

Stereolithogrophy (SLa) is a process where resin is cured with light in layers. The advantage of this method is accuracy and quality of finish. The disadvantages of this method are material choice and ultimately material strength. SLa parts may have a support structure that needs to be removed. This is the most expensive process.

Selective Laser Sintering (SLS) is a process where powdered material is fused by a laser in layers. The advantage of this method is strength of material and accuracy. The disadvantage is material choice and surface finish. SLS parts require no support structure as the part is supported by the powder that it sits in. This process is cheaper than SLa.

Fused deposition modelling (FDM)(FFF) is where an extruded plastic filament is fed into a heated nozzle and melted into position in layers. The advantages of this method are low cost, availability of inexpensive printers, material choice and strength. The disadvantages are low accuracy and poor surface finish. FDM parts typically have a support structure but this can be done with a second material that is either water soluble or breaks away easily.

There are other types of 3D printing technology but in basic terms you either fuse powder, cure resin or melt filament using different methods. So which method do you choose? Do you buy a printer and do it yourself or do you choose a supplier and buy from them? Let’s look at the pros and cons of each method.

FDM (FFF) parts

Pros – Low-cost parts to make, lowest printer costs, Easiest printer to use, no post processing required.

Cons – Lowest accuracy parts, poor surface finish, parts can be weak in one dimension due to the layers

Uses – Low-cost prototypes, simple internal parts, jigs and fixtures.

SLA parts

Pros – Highest accuracy parts, best surface finish.

Cons – Parts tend to be brittle and don’t age well, more expensive printers, several post processes required before parts can be used.

Uses - high quality prototyping, master models for cold casting.

SLS parts

Pros – parts are tough with good dimensional accuracy; parts are low cost.

Cons – Parts have a rough finish, generally off white unless dyed, printers are more expensive to buy, messy to use due to the powder.

Uses – Functional prototype parts for mechanisms where flex or load may occur. Ideal for tough internal parts in production.

In conclusion, I would consider SLS or FDM parts suitable for production use and would consider these three scenarios something worth thinking about.

1.Small internal components that are difficult to make or require investment in a tool required in lower volumes.

2.Combining parts – can several moulded or machined parts be made into one printed part?

3.Customisation – Can your design be made customisable to accommodate individual fitment for instance?

Now let's look at the basic types of subtractive manufacturing technologies.

As the name suggests, this is about removing material to create a part rather than adding it. This typically relates to CNC machining of metal and plastic parts. There is little in the way of affordable units for in house subtractive manufacturing bar a few small CNC desktop prototyping units, so this is typically sourced from 3rd party specialists or is already integral to the business you are running. Parts made by a subtractive method are as accurate as you need them to be, and the choice of materials is limited only by what you can cut. Prices tend to be higher due to quality and accuracy, but subtractive manufacturing gives you flexibility to produce low volumes without up front investment. Worth considering for the right product!

Conclusion

In answer to the original question, the answer really depends on your product. A new or existing product could well benefit from these manufacturing techniques under the right circumstances. Employing the right design partner will help work through these questions and find the right solutions to cost effective manufacture.

With the New Year holiday now behind us, I thought it would be a good idea to post up a blog to let all of our followers know about the current situation with obtaining grants for research, innovation and the development of new products.

InnovateUK – Formally the Technology Strategy Board (TSB) is a really good place to start looking for funding. Funding is done through competitions. Some are quite focussed on a specific area of science or expertise, some are focussed more on a specific stage of the development process. The preferred markets are emerging and enabling technologies, health and life sciences, infrastructure systems, and manufacturing and material.

Go to https://www.gov.uk/government/organisations/innovate-ukfor more information.

R&D Tax relief/credits – If you are liable for corporation tax, i.e. you are a UK trading company, you are potentially eligible for R&D tax relief/credits. For SME’s this could give you up to 33% back, for larger corporations up to 10%. A project qualifies if it constitutes an "advance†in science and technology, and that’s defined as an improvement in overall knowledge and capability in a technical field. An example to clarify: You wouldn’t get funding for a project to re-design a screwdriver with a new handle, but you might qualify if the handle was made of a new material with technical properties.

Go to https://www.gov.uk/guidance/corporation-tax-research-and-development-rd-relieffor more information.

Horizon 2020 – is an EU framework programme for research and innovation. The UK Government has chosen to underwrite Horizon 2020 projects beyond the UK’s exit from the EU so it looks like funding for UK companies is still possible but I would advise checking the situation if you’re thinking about applying.

Go to https://ec.europa.eu/programmes/horizon2020/en/what-horizon-2020for general information.

The 2016/17 programme is here http://ec.europa.eu/research/participants/data/ref/h2020/wp/2016_2017/main/h2020-wp1617-intro_en.pdf

Eurostars – is a research and development funding programme aimed at SME’s. It is a joint venture between Eureka and the European Commission through Horizon 2020. In the UK, it is only research performing SME’s are eligible and this looks to be in conjunction with Innovate UK.

Go to https://www.eurostars-eureka.eu/about-eurostarsfor more information.

The Patent Box – This is a relatively new scheme to allow companies that hold Patents to claim a reduced corporation tax rate on profits made from IP. As of April 2013, a company can reduce CT to 10%. Companies that are licensing IP from an IP holder can also claim this lower tax but must meet the criteria.

Go to https://www.gov.uk/guidance/corporation-tax-the-patent-boxto find out more.

In a study of more than 100 start-ups, a technology venture capital organisation found that the number one cause of start-up failure was "no market need.” Nearly half of these start-ups spent years building a product before they found out that they were wrong in their most central assumption: that anyone was actually interested in that product in the first place!

What they should have done was adopt a minimum viable product approach. "What is a minimum viable product” I hear you ask! Read on….

Traditionally, products are conceived and developed behind closed doors, based on research and a lot of assumptions about what the target audience want. This typically takes a long time and a lot of money to get to a production ready product. What happens if the product you develop is not what your customers want? You’ve spent time and money developing what you believe to be the next big thing and no one’s interested! Maybe the target audience has changed in the two years you took developing it. Maybe your research was not good enough and you’ve been developing something that no one ever wanted. Maybe you’re close with the product you’ve developed but something is not quite right and it just doesn’t gel with your customers.

Failure can be avoided by adopting a Minimum Viable Product (MVP) approach. It’s not right for every development but can be very effective when implemented on the right project.

The start of your project will look the same as the traditional approach. You’ll look at the market, the target users and the competition. You’ll develop a product brief and ideate concept designs to fulfil the needs. The big difference with the MVP approach is that you identify the core feature(s) of the new product and aim to develop a simplified version of your product as quickly and cost effectively as possible and get feedback on it from your target audience. The idea is to maximise the amount of validated learning for the lowest investment in the fewest steps. In its simplest form, a physical MVP is a short run of prototypes that you use for early trials with select customers.

For physical products, you may not have to develop a product at all initially. An explainer video showing how your new product works could be enough to get feedback. Perhaps it could just be a landing page for your new product on your website as this could give you early feedback on potential popularity. Many start-up’s use Crowd funding sites like Kickstarter to get their message across and to tweak their proposition to align with the feedback they receive. Some companies who develop products with bespoke integrated electronics onboard, concentrate on the core functionality of the device first and only consider adding other less important features to enhance the product once this has been perfected.

Most importantly it is about listening to the feedback that this early product, explainer video or landing page yields and to feed that back into the design to improve the final product and make it a class leading one.

That’s a very brief explanation of what an MVP is and why you should seriously consider it for your next product development. Why not contact a design consultancy today and talk to them about it.