Call Us: 01702 292984 Email Us: info@cube3productdesign.co.uk

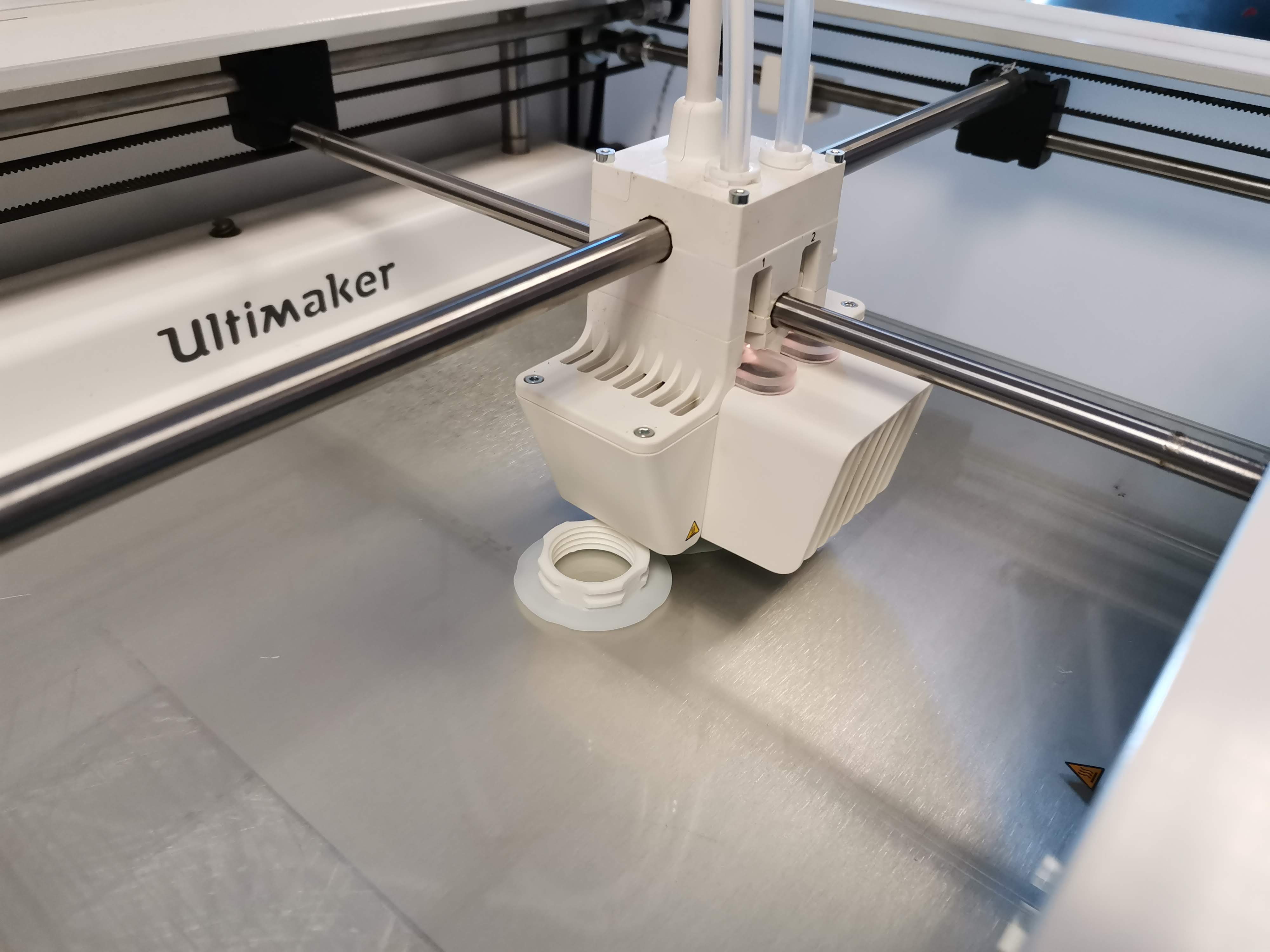

How useful is an Ultimaker S5 with material station?

Well, pretty damn good! It allows us to print in different materials with different support material if required with little or no set up. We run two glass build plates so as soon as one print finishes, we remove the model and build plate, replace with a clean one and it's ready for someone else to use right away. We even use it remotely from home by connecting remotely with our office computers and sending prints direct to the printer.

3D printing is not perfect and there are always issues. For a larger more complex print we always ensure someone is on hand to check that all is well for the first hour or so just in case there is a problem. We had to replace the print head once after a catastrophic disaster where a large complex build lost adhesion to the build plate quite early on and ended up turning the print head into a giant ball of plastic! Lesson learnt!

Some materials are not possible to run through the material station. We have failed to reliably print in TPU as the route from spool to print head is too torturous for the soft material and it gets stuck! Polyprop is currently working reliably but we have similar issues.

Ultimately, the purpose of the Ultimaker S5 was to give us an easy to use, reliable print solution in house to allow us to print development ideas as and when we need them. We rarely use it to print customer facing prototypes unless they are for functional demonstration only. The Ultimaker S5 has turned out to be a valuable addition to the development team and we could not continue without it. We still have much to learn about using it and would like to explore interesting materials as well as innovative ways to use it.