Call Us: 01702 292984 Email Us: info@cube3productdesign.co.uk

The final stage of any project is to ensure that it is fully engineered and is supported where necessary with a data pack for manufacturing. The quality of this data is vital to the smooth transition to production. If the information produced at the end of a project is not fully documented and revision managed, who knows what you may end up with 6 months down the line!

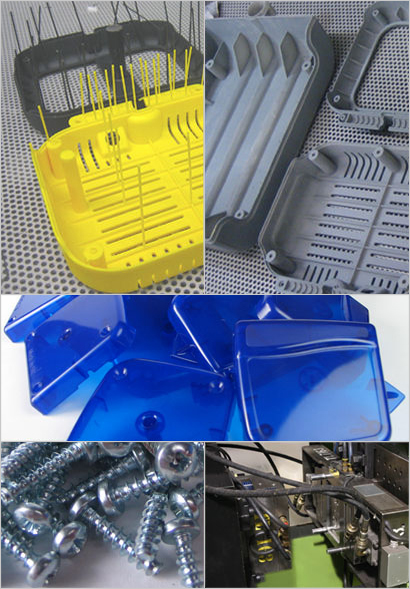

Fits and tolerancing - Any product that is destined for manufacture should have been fit and tolerance engineered to ensure that all parts go together as intended.

Revision managed data pack - To ensure that your production partners build your product to a known standard is vital. The data pack is to define the manufactured product to ensure quality and avoid production problems.

Manufacturing liaison - If a project has moulded, cast, stamped or extruded parts it is essential to work closely with your tooling partners to ensure that parts have been made to the right specification. We oversee this transition period from the virtual world to the real world by working closely with manufacturing partners.

Pre-production samples - We have a workshop and storage facility allowing us to get involved with assembling pre-production batches prior to full production. This can be useful on more complex products to iron out any assembly procedures before committing to full production assembly.

Call 44 (0) 1702 292984 to find out more or use the contact form here >

For a free no-obligation consultation you can contact us on 44 (0) 1702 292984 or click below to send us an email.

Email us